- YUHONG-Markenartikel wurden bereits in über 85 Länder exportiert. Mit über 35 Jahren Erfahrung, aufgrund der strengen Qualitätskontrollrichtlinien, des exzellenten Verkaufsservices und der pünktlichen Lieferung. YUHONG gewann immer mehr neue Kunden und erhielt immer mehr Nachbestellungen von alten Kunden. In der Denkweise der YUHONG-Mitarbeiter gilt: Qualität ist das Wichtigste!

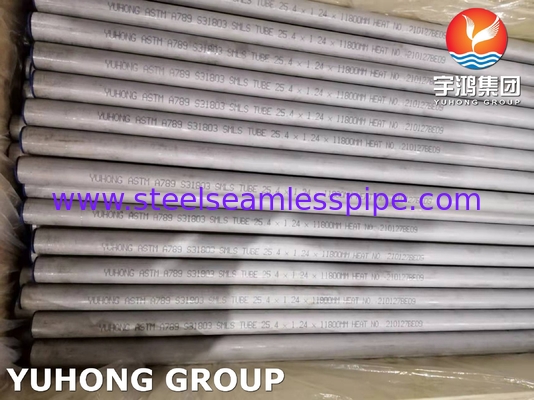

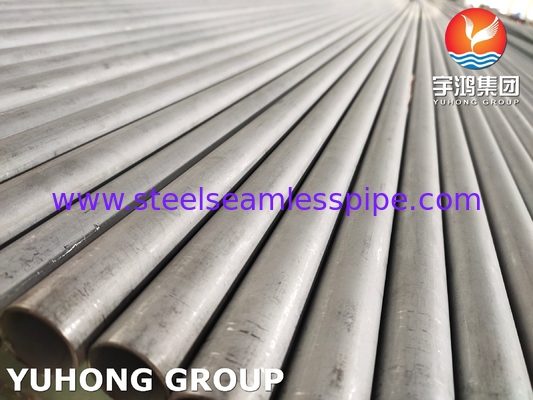

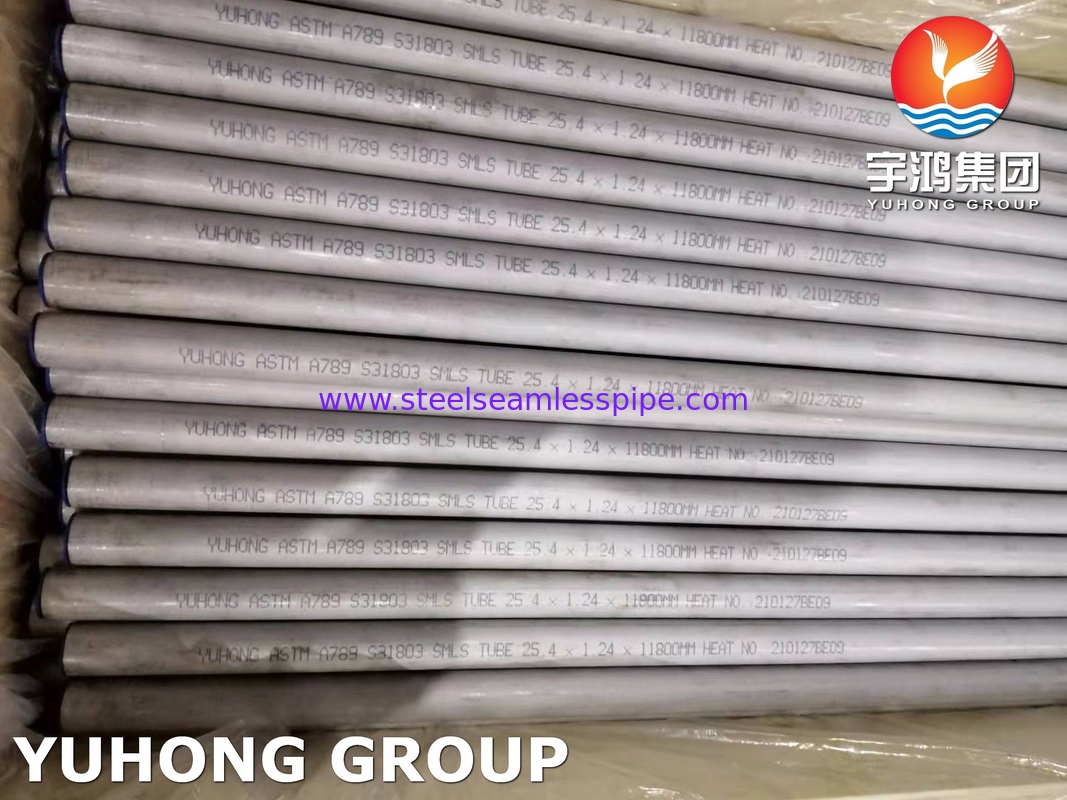

ASTM A789 UNS S31803 1.4462 Nahtlose und geschweißte Duplex-Edelstahlrohre

ASTM A789 UNS S31803 (1.4462) Nahtlose und geschweißte Duplex-Edelstahlrohre ist ein hochleistungsfähiges, korrosionsbeständiges Stahlrohr, das für anspruchsvolle industrielle Anwendungen entwickelt wurde. Es wird aus Duplex-Edelstahl (austenitisch-ferritische Struktur) hergestellt und bietet ausgezeichnete Festigkeit, Lochfraßbeständigkeit und Beständigkeit gegen Spannungsrisskorrosion. Dieses Produkt ist sowohl in nahtloser als auch in geschweißter Form erhältlich,mit einer kontrollierten durchschnittlichen/minimalen Wandstärkeum die strukturelle Integrität unter Hochdruck- und rauen Umgebungsbedingungen zu gewährleisten. Es wird häufig in der Öl- und Gasindustrie, der chemischen Verarbeitung, der Entsalzung und im Schiffbau eingesetzt.

1. Chemische und mechanische Eigenschaften

| ASTM A789 UNS S31803 Chemische Zusammensetzung (%) |

| C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

| ≤ 0,030% |

≤ 2,00% |

≤ 0,030% |

≤ 0,020% |

≤ 1,00% |

21,0 - 23,0% |

4,5 - 6,5% |

2,5 - 3,5% |

0,08 - 0,20% |

Mechanische Eigenschaften

| Eigenschaft |

Standardwert |

| Zugfestigkeit |

620 - 795 MPa |

| Streckgrenze (0,2% Dehnung) |

≥ 450 MPa |

| Dehnung |

≥ 25% |

| Härte (Brinell) |

≤ 32 HRC |

| (-46°C) Kerbschlagzähigkeit (-46°C) |

≥40 J |

Wichtige mechanische Eigenschaften

- Hohe Festigkeitseigenschaften

- Ausgezeichnete Zähigkeit

- Ausgezeichnete Ermüdungsverhalten

- Physikalische Eigenschaften

2. Wichtige Vorteile

- Überlegenes Festigkeits-Gewichts-Verhältnis

Hohe Festigkeitseigenschaften: Die Streckgrenze (≥450 MPa) ist doppelt so hoch wie die von Edelstahl 304, wobei die Zugfestigkeit (620-795 MPa) die herkömmlichen austenitischen Güten deutlich übersteigt.

Gewichtsreduzierung: Ermöglicht 20-30% Materialeinsparung im Vergleich zu Standard-Edelstählen bei äquivalenten Druckwerten.

-

Hervorragende Korrosionsbeständigkeit

Doppelschutz: Synergistischer Effekt von Cr(21-23%)+Mo(2,5-3,5%)+N(0,08-0,20%)

Spezifische Beständigkeit: Chloridspannungsrisskorrosion, Lochfraß-/Spaltkorrosion (PREN≥35), saure Medien

Geringere Lebenszykluskosten: 40-60% Einsparungen gegenüber Nickellegierungen, 2-3x Lebensdauer gegenüber 316L

Einfache Installation: Ausgezeichnete Schweißbarkeit (kein PWHT erforderlich), CTE ähnlich wie Kohlenstoffstahl (13,5×10⁻⁶/℃)

Großer Temperaturbereich: Stabile Leistung von -50℃ bis 300℃

Vorteile der Doppelphase: Ferritphase für Festigkeit + Austenitphase für Zähigkeit

3. Wichtige Anwendungen

Unterwasserpipelines, X-Mas-Tree-Komponenten, LNG-Wärmetauscher

Reaktoren, Kristallisatoren, Beizanlagen

Hochdruck-RO-Behälter, Soleheizungen

Geothermie-Gehäuse, Wasserstoffspeicherung

Auswahlhilfe

- Kombination aus hoher Festigkeit und Korrosionsbeständigkeit

- Chloridhaltige Medien

- Gewichtsempfindliche Hochdrucksysteme

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!